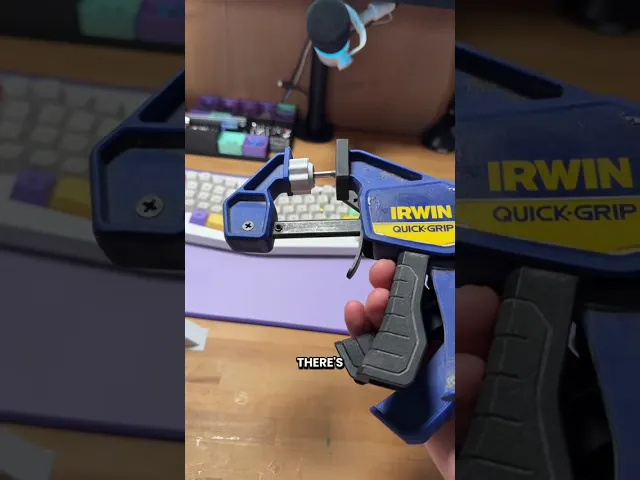

Irwin Clamp Desk Press

October 6, 2025

Table of Contents

Download

Overview

Watch the short videos I made while designing this part:

For the past year, I have been using these Irwin clamps to hold two things together that I needed to glue. Almost always, they are these ¼-20 screws and a 3D printed part. I would always just lay the clamp down on the desk, but I don't have a lot of space and it always took up too much of it. So I designed this base that the clamp could be inserted into and screwed in, so the clamp could sit up straight and stand upright on it's own.

If you want to see a few of the short videos I made about the design process, see here.

The original design, “modular base”, had a dovetail slot in the top, so if you wanted to design your own platform or jig to make whatever you were gluing easier to work with, you could. I left a spot on the side for a heat insert, so you could slide in different attachments and screw them into place. Please be advised that I designed this, but never ended up printing it myself to test tolerances and fit. I would recommend double checking this before you go and print the whole thing or print the standard base instead. The 1 issue with this design is because of the clearance needed for the dovetail, the clamp doesn't meet the surface when it's all the way down. Which is what lead me to the second design.

The “standard” main base just has a much taller base, so when the clamp is all the way down, it meets the base. I didn't really like how much more filament was going to be needed to make this happen, which is why I included a variation of the standard base called “skinny”. That's the one in the pictures.

I've included the .STEP files for everything in case you wanted to tweak this to fit your work. I printed mine with Elegoo Glass Fiber PETG and it is extremely solid. I clamped this as hard as I could and it did not even make a creaking sound. Very impressed. Love that filament.

Tools

Filament used: Elegoo PETG-Glass Fiber Black

Parts

Clamp

Hardware

(I used socket head screws from this set for mine but use whatever you want)

x1 m4 x 20mm screw

x1 m4 x nut

x1 m4 washer (optional)

x1 m2 x 20mm screw

x1 m2 x nut

x1 m2 washer (optional)

Assembly Guide

Bed adhesion:

Brim type → No-brim

Prime tower:

Enable → false

Speed:

initial_layer_infill_speed → 60

initial_layer_speed → 30

inner_wall_speed → 200

Strength:

Skeleton infill density → 25%

Skin infill density → 25%

Sparse infill density → 25%

Sparse infill pattern → Gyroid

Top/bottom shells:

Top solid layers → 9

Walls:

Wall loops → 5

Wall generator:

Wall generator → Arachne

Advanced:

Order of walls → inner wall/out/inner wall